Rubber & Polyurethane Bonding Services in Australia

Dorlen Rubber provides specialist joining and adhesion services for rubber and polyurethane components used in demanding industrial, commercial, and infrastructure applications across Australia. Manufactured locally in Adelaide, our bonded assemblies are engineered to deliver long-term adhesion, structural integrity, and reliable performance in harsh operating environments.

This process allows different materials to be permanently joined, combining their individual properties into a single, high-performance component. Dorlen Rubber works closely with engineers, maintenance teams, and procurement professionals to deliver fit-for-purpose composite solutions where mechanical fastening alone is not suitable or effective.

Our in-house capabilities support both rubber and polyurethane materials joined to a wide range of substrates, enabling durable assemblies tailored to specific application requirements.

Built for performance. Made to last.

Material Joining Capabilities

Dorlen Rubber offers in-house joining services for a broad range of material combinations, providing flexibility in design, performance outcomes, and component lifespan.

Rubber Bonding Capabilities

We work with rubber materials permanently joined to:

Metal

Fabric

Concrete

Fibreglass

Polyurethane

Rubber-to-rubber assemblies

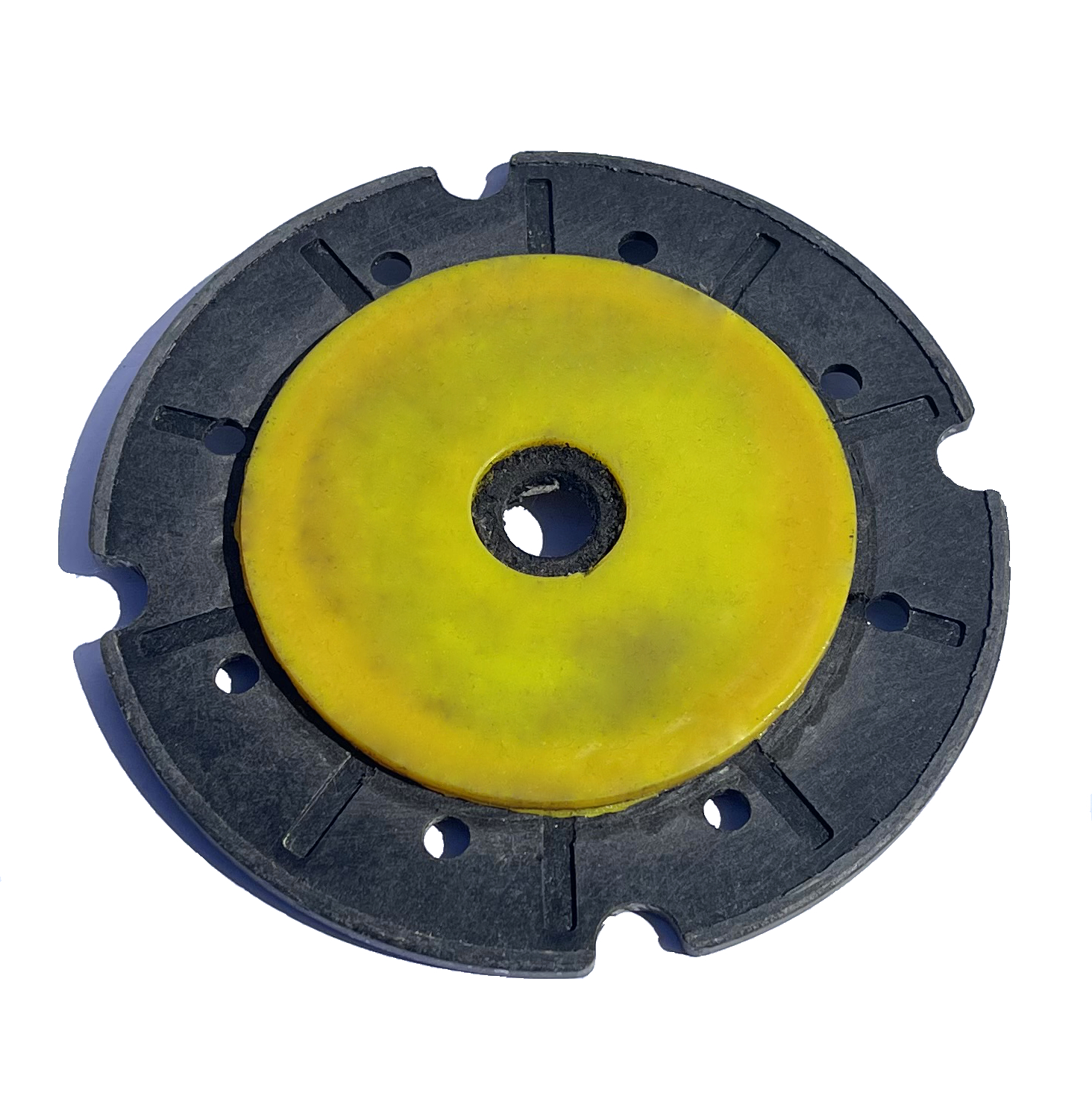

These assemblies are commonly used where vibration control, impact absorption, sealing, or wear resistance is required. Typical applications include mounts, buffers, protective linings, and composite components used in industrial environments.

Polyurethane Bonding Capabilities

In addition to rubber, Dorlen Rubber also provides joining solutions for polyurethane components combined with:

Metal

Rubber

Fabric

Concrete

Fibreglass

Polyurethane-to-polyurethane assemblies

Polyurethane-based assemblies are often specified where high abrasion resistance, load-bearing capacity, and long service life are critical. These components are commonly used in rollers, wheels, wear surfaces, and impact-resistant applications.

Surface Preparation & Adhesion Processes

Achieving reliable long-term adhesion requires careful surface preparation, material compatibility assessment, and controlled processing. Dorlen Rubber applies proven preparation methods and processing techniques to ensure strong attachment and consistent results.

Preparation and joining processes typically involve:

Thorough surface cleaning and inspection

Mechanical or chemical surface activation

Application of appropriate primers or adhesion agents

Controlled curing and finishing processes

Each solution is selected based on material type, operating conditions, environmental exposure, and performance requirements.

Applications of Bonded Rubber & Polyurethane Components

Joined rubber and polyurethane assemblies are used across a wide range of industrial applications, including:

Vibration mounts and isolators

Impact buffers and stops

Wear linings and protective coatings

Rollers, wheels, and composite wear surfaces (including pottery wheels)

Seals, gaskets, and hybrid assemblies

Structural protection and lining systems

These assemblies help absorb vibration, reduce noise, resist wear, and withstand repeated mechanical stress in demanding operating conditions.

Industries We Support

Dorlen Rubber supplies composite rubber and polyurethane components to industries including:

Manufacturing and automation

Mining and resources

Infrastructure and construction

Industrial machinery and equipment

Material handling and processing

Defence and heavy industry

Our services support both new component manufacture and refurbishment or replacement applications, helping extend asset life and reduce downtime.

Why Choose Dorlen Rubber?

Australian-owned and operated manufacturer

In-house rubber and polyurethane bonding

Wide range of material combinations

Proven surface preparation and bonding processes

Consistent quality control and testing

Practical technical advice and support

Dorlen Rubber focuses on delivering bonded components that perform reliably in real-world industrial environments.

Trusted Australian Manufacturer

Dorlen Rubber is a trusted Australian specialist, supplying custom rubber and polyurethane assemblies nationwide. Local manufacturing allows direct collaboration, faster response times, and strict quality control throughout the production process.

By keeping all preparation and joining processes in-house, we ensure every assembly meets specification, delivers reliable adhesion, and performs as intended over its service life.

Talk to Dorlen Rubber About Bonding Solutions

If your application requires rubber or polyurethane bonded to metal, fabric, concrete, fibreglass, or other substrates, Dorlen Rubber can help develop a reliable, long-lasting solution tailored to your requirements. Contact us today for a quote!