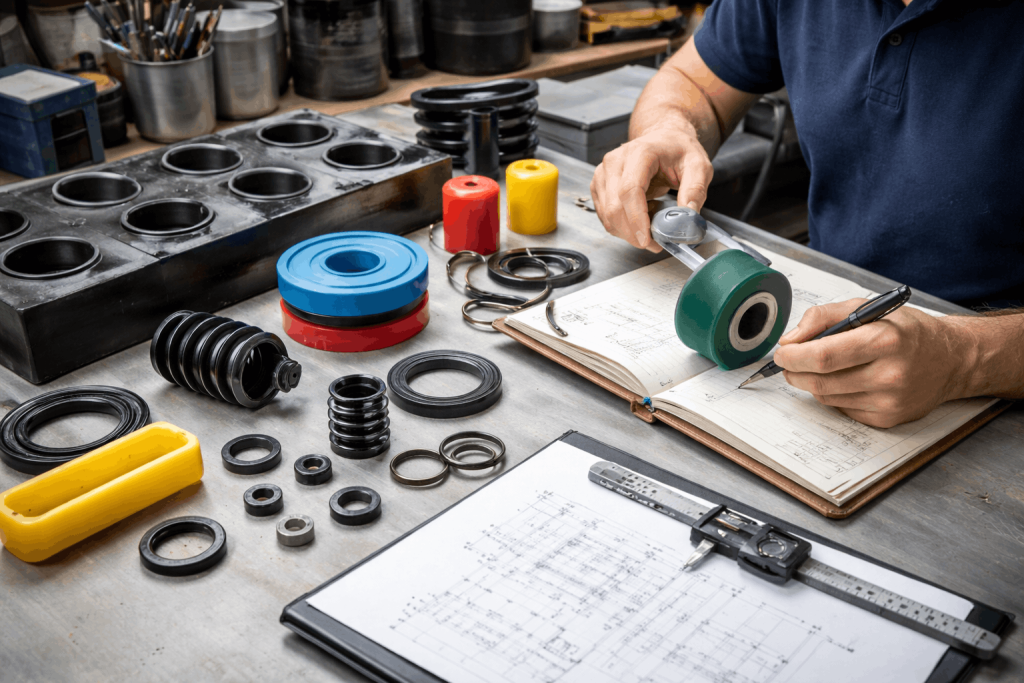

Rubber & Polyurethane Project Capabilities

Dorlen Rubber supports a wide range of custom projects involving rubber and polyurethane materials, including:

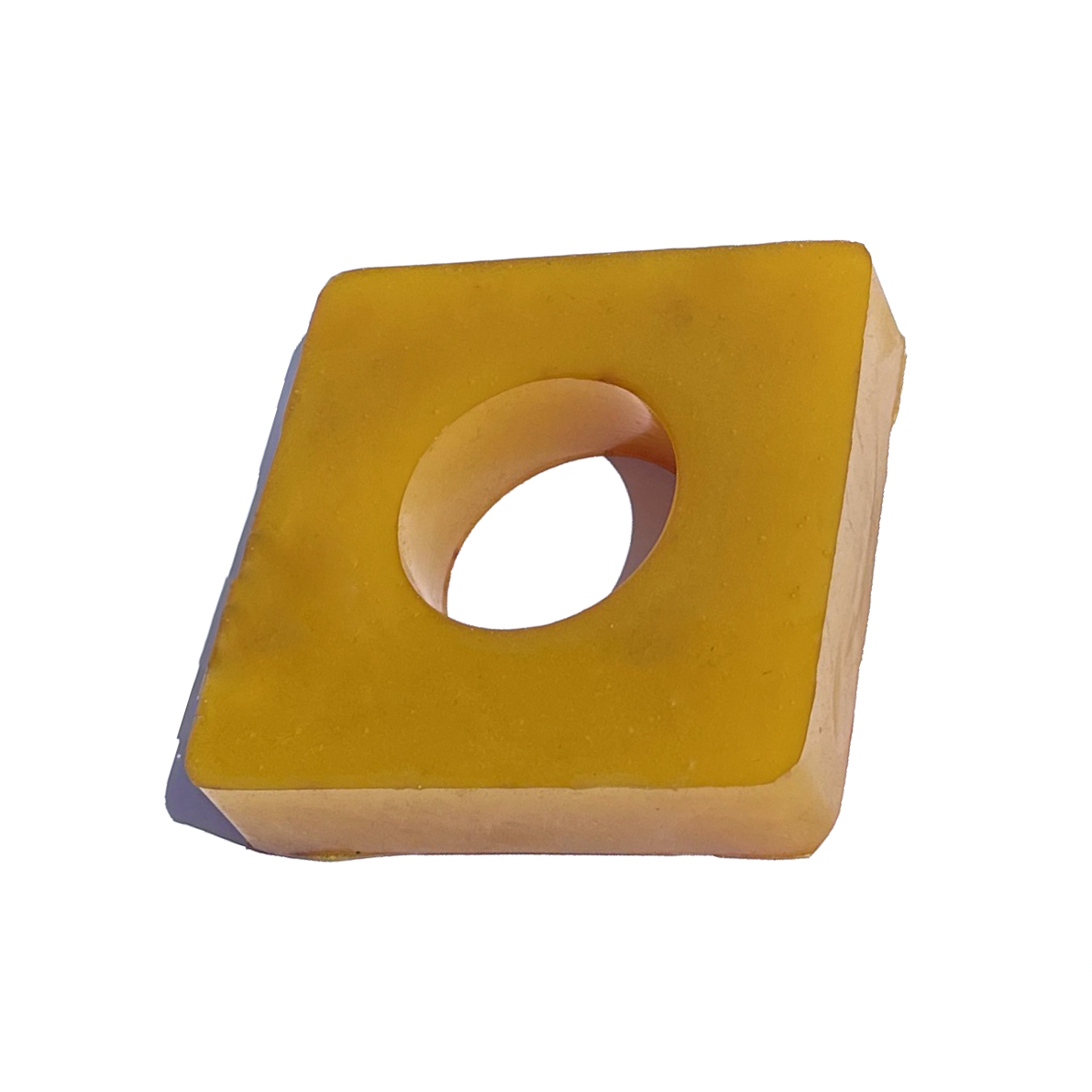

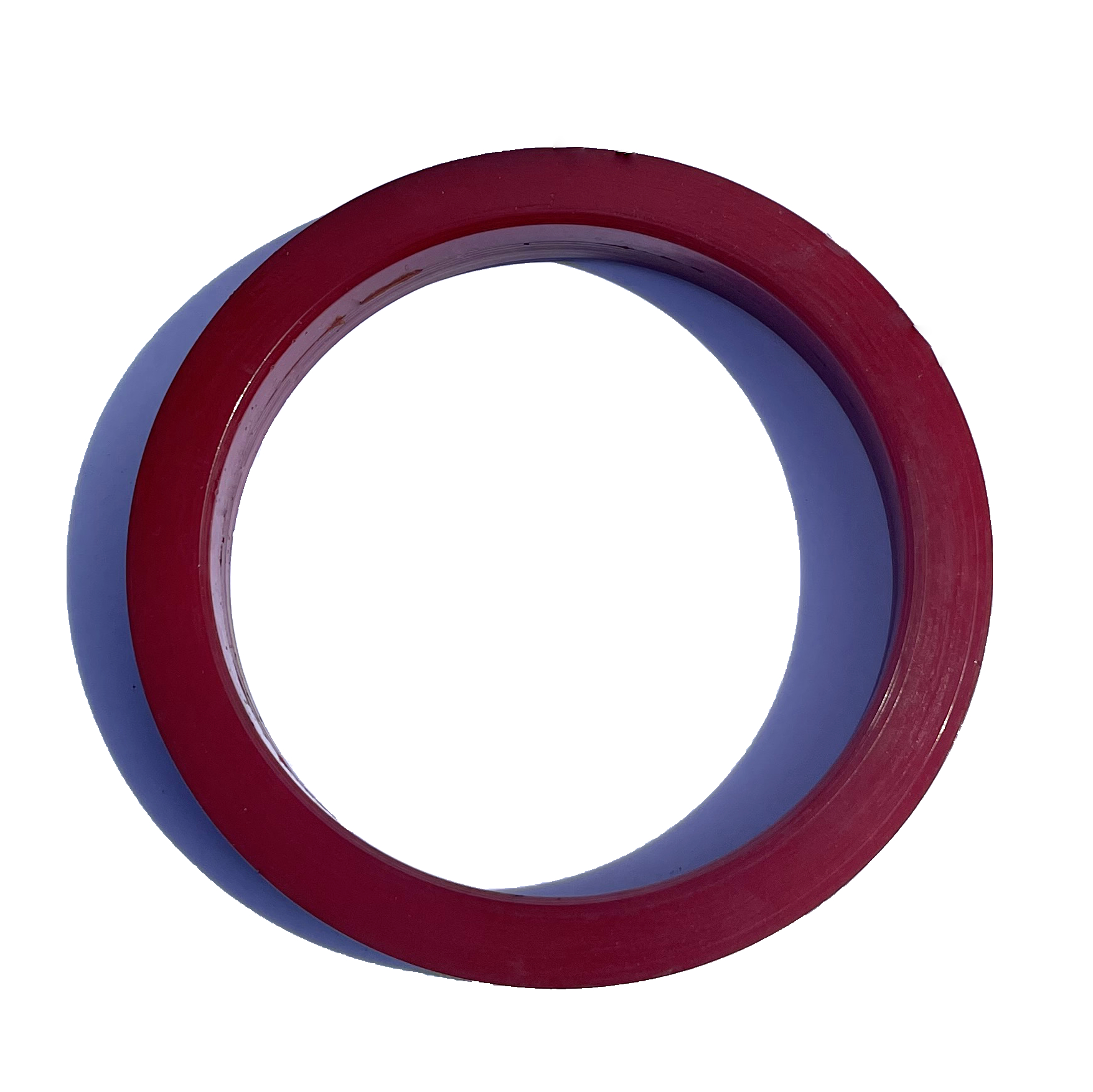

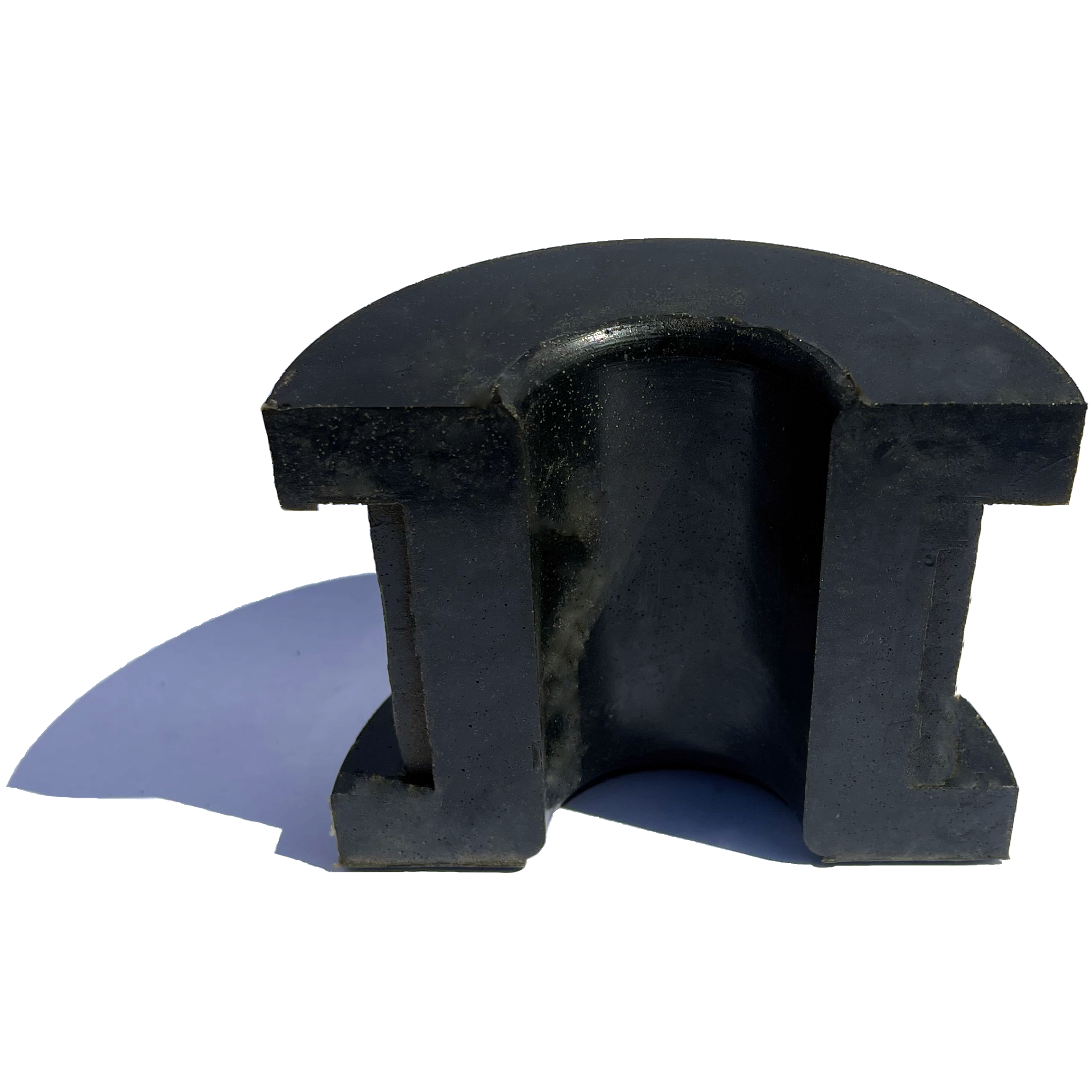

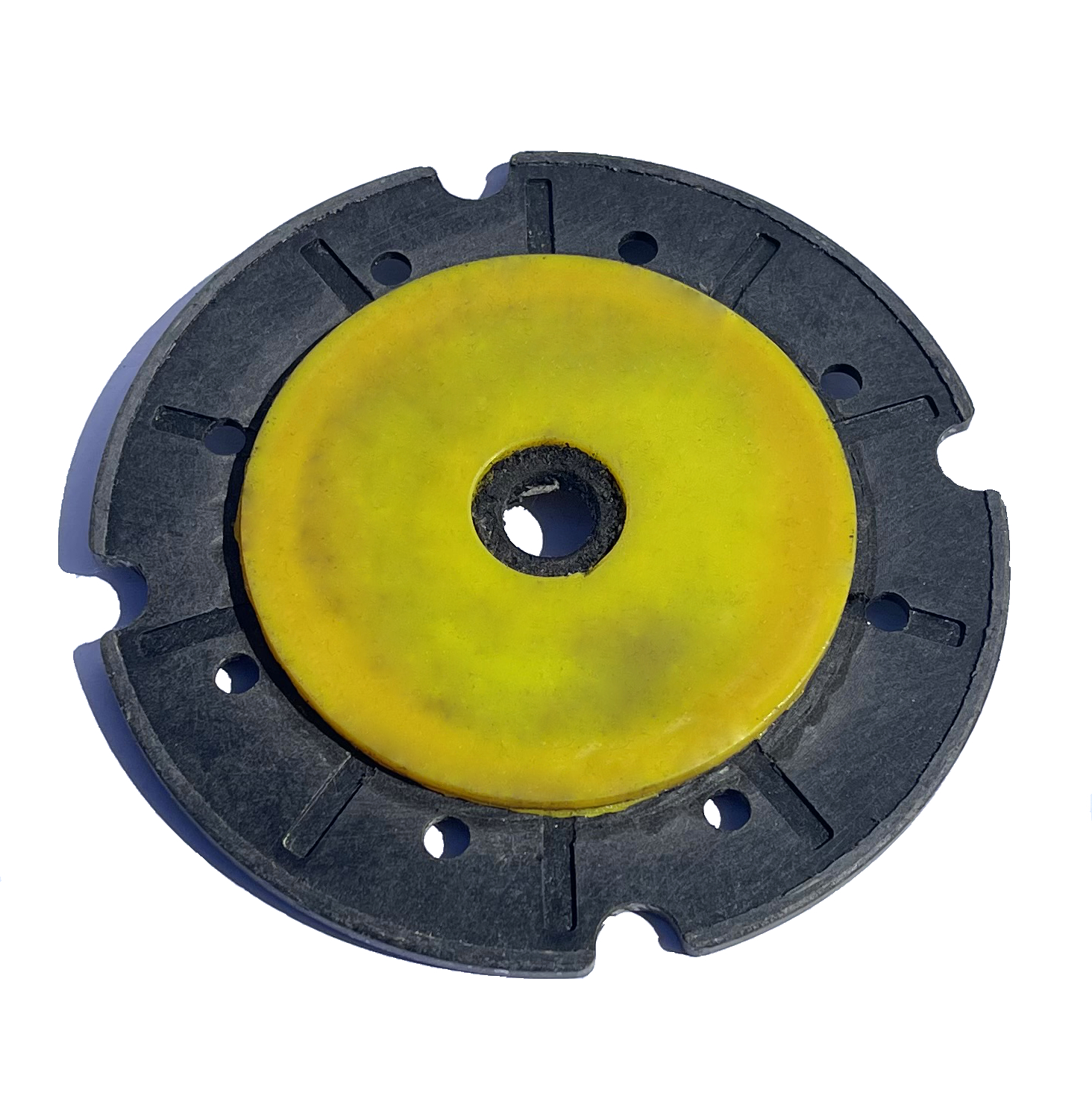

Compression moulded rubber components

Rubber extrusions

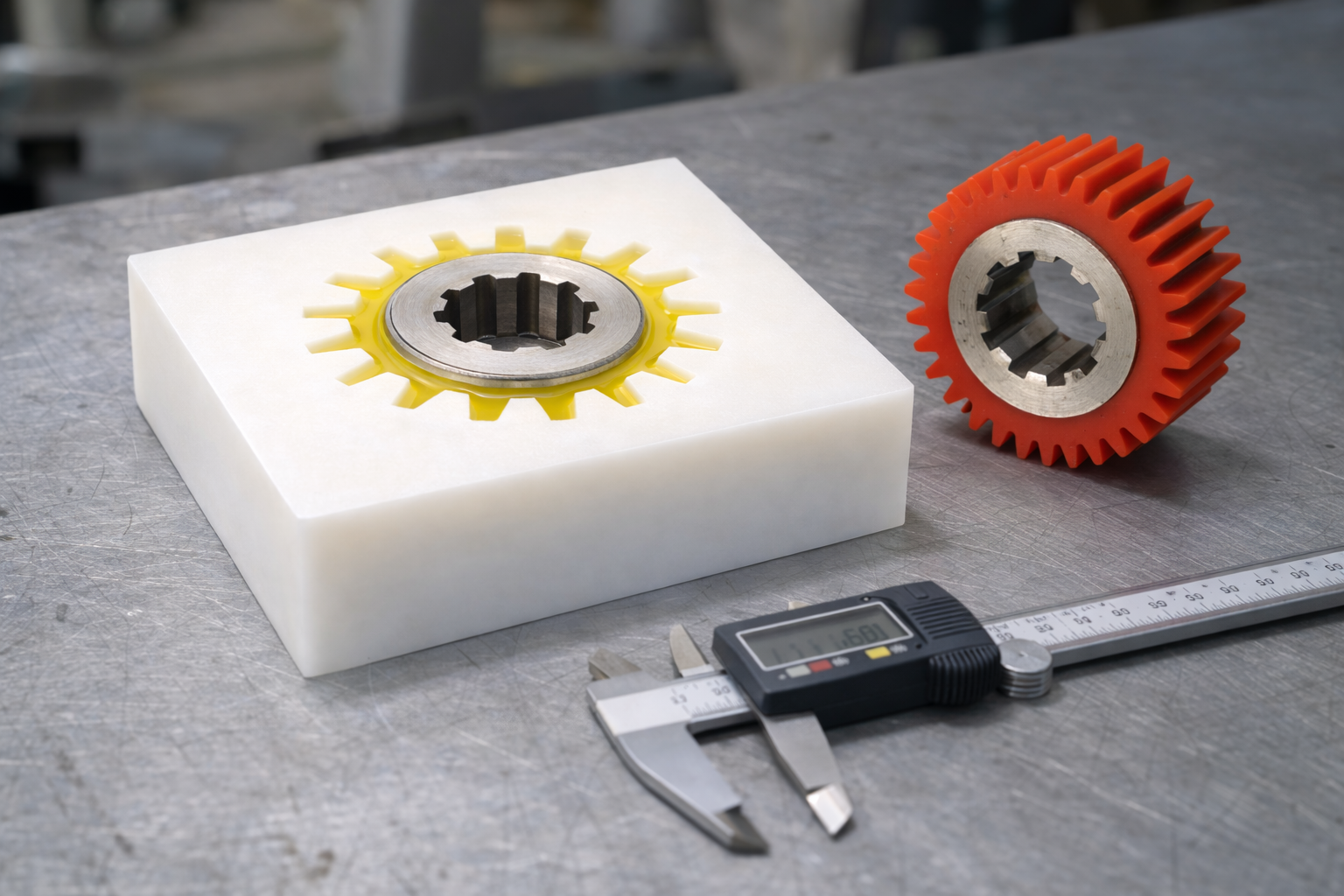

Polyurethane cast parts and wear components

Rubber and polyurethane bonding to metal, fabric, concrete, and composites

Industrial sheeting, pads, and protective linings

Refurbishment of rollers, wheels, and bonded assemblies

By combining multiple manufacturing processes under one roof, projects can be streamlined without relying on multiple suppliers.