Custom Rubber Extrusion Services in Australia

Dorlen Rubber provides custom rubber extrusion services for industrial, commercial, and infrastructure applications across Australia. Manufactured locally in Adelaide, our extruded rubber products are designed for consistency, durability, and reliable performance in demanding environments.

Rubber extrusion is ideal for producing continuous rubber profiles with a uniform cross-section. Dorlen Rubber works closely with engineers, maintenance teams, and procurement professionals to manufacture extruded rubber components that meet exact dimensional and performance requirements.

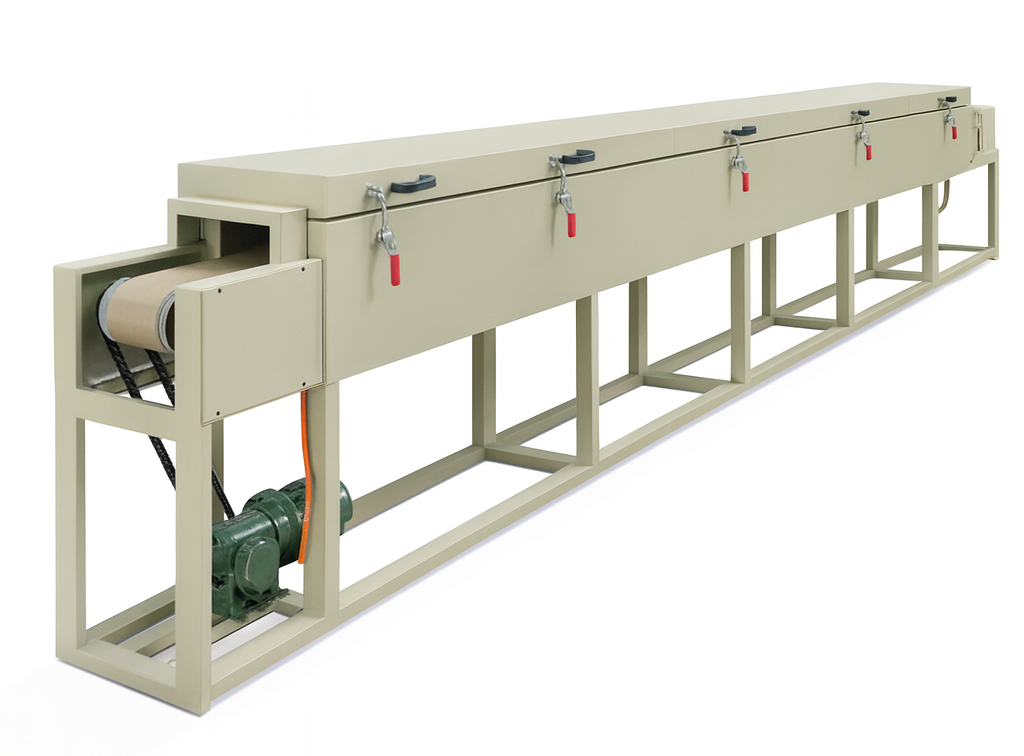

All rubber extrusion is produced in-house using a hot air vulcanisation (HAV) tunnel, ensuring controlled curing, consistent quality, and repeatable results.

Australian-made. Custom engineered. Industry trusted.

Rubber Extrusion Capabilities

Dorlen Rubber specialises in precision rubber extrusion supported by proven processing methods and material expertise. Our extrusion capabilities allow us to manufacture both standard and custom-designed rubber profiles for a wide range of applications.

Rubber Extrusion Size Range

We can manufacture rubber extrusions within the following dimensions:

Minimum size: 4mm × 4mm

Maximum size: 70mm × 70mm

This range allows us to support everything from small sealing profiles through to larger industrial rubber sections.

Hot Air Vulcanisation (HAV) Rubber Extrusion

Dorlen Rubber utilises a hot air vulcanisation tunnel to cure extruded rubber profiles. HAV extrusion provides uniform heat exposure during curing, resulting in consistent material properties and dimensional stability throughout the length of the extrusion.

This process is well suited to producing high-quality rubber profiles with reliable performance characteristics, particularly where consistency and repeatability are critical.

Benefits of Hot Air Vulcanisation

Uniform curing across the profile

Consistent mechanical properties

Improved dimensional accuracy

Suitable for a wide range of rubber compounds

Our HAV extrusion process supports both short runs and ongoing production requirements.

Extruded Rubber Products

Dorlen Rubber manufactures a wide range of extruded rubber products, including:

Rubber seals and gaskets

Edge trims and protective profiles

Continuous rubber strips

Weather seals

Custom extrusion profiles

All extrusions can be produced to customer-supplied drawings or developed in consultation with our team to suit specific applications. Contact us today to make your profile a reality!

Rubber Compounds Available

Dorlen Rubber works with a wide range of rubber compounds to suit different operating environments, performance requirements, and industry standards.

Standard In-Stock Rubber Compounds

The following compounds are regularly stocked and available for shorter lead times:

- Nitrile (NBR)

- EPDM

These compounds are commonly used for industrial sealing, extrusion profiles, and general-purpose applications where oil resistance, weather resistance, and durability are required.

Additional Rubber Compounds (Extended Lead Time)

We can also manufacture rubber extrusions using the following compounds, subject to additional lead time for material procurement:

- Natural Rubber

- Neoprene

- Butyl

- Viton

- HNBR

- Hypalon

- Silicone

- SBR

- Polybutadiene

- Custom compound blends

These materials are selected based on application requirements such as chemical resistance, temperature range, flexibility, abrasion resistance, and environmental exposure.

Our team will advise on the most suitable compound and lead time based on your performance needs and production schedule.

Why Choose Dorlen Rubber ?

- Australian-owned and operated manufacturer

- In-house tooling and hot air vulcanisation extrusion line

- Extrusion sizes from 4mm × 4mm to 70mm × 70mm

- Custom profile development and support

- Consistent quality and reliable lead times

Dorlen Rubber focuses on delivering practical rubber extrusion solutions that perform reliably in real-world industrial conditions.

Applications & Industries

Our rubber extrusion services support a wide range of industries and applications, including:

Manufacturing and automation

Construction and infrastructure

Industrial equipment and machinery

Transport and material handling

Sealing and protection systems

Extruded rubber components are commonly used for sealing, edge protection, vibration control, and general industrial protection.

Trusted Australian Manufacturer

Dorlen Rubber is a trusted Australian rubber extrusion manufacturer, supplying custom extruded rubber products nationwide. Our local production allows for direct communication and faster turnaround times

Request a Rubber Extrusion Quote

Looking for a reliable rubber extrusion supplier?

Contact Dorlen Rubber to discuss your extrusion profile, compound selection, and dimensional requirements.