In-House Rubber and Polyurethane R&D Services

Dorlen Rubber provides rubber & polyurethane R&D (research and development) services to support the design, optimisation, and manufacture of components for demanding industrial applications. Based in Adelaide, our technical team works closely with clients to improve part performance, extend service life, and streamline production outcomes.

R&D plays a critical role in ensuring components perform as intended in real-world conditions. Dorlen Rubber’s development capability supports both new product development and improvement of existing components, helping clients reduce failures, improve reliability, and achieve better long-term value.

Built for performance. Made to last.

Rubber & Polyurethane R&D Services - Supporting Better Component Performance

Our research and development services are focused on practical outcomes, not theoretical design. We work directly with engineers, maintenance teams, and procurement professionals to understand how components are used in service and where improvements can be made.

By combining hands-on manufacturing experience with material and process knowledge, Dorlen Rubber helps clients make informed decisions around design, tooling, and production methods.

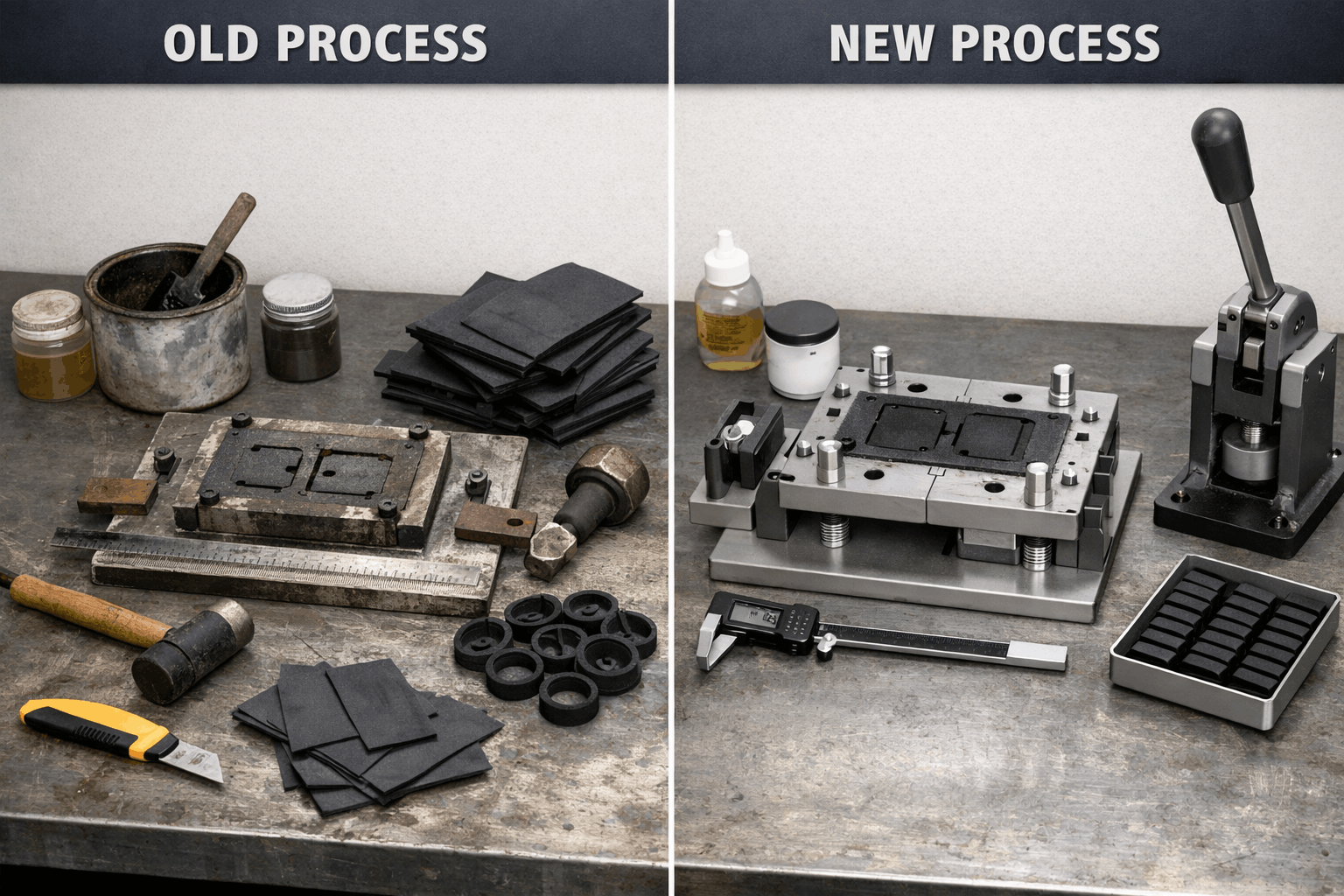

Design Review & Tooling Optimisation

Dorlen Rubber assists customers by reviewing and refining existing rubber and polyurethane component designs. This often includes evaluating mould design, tolerances, and part geometry to improve accuracy, consistency, or ease of manufacture.

Rubber & Polyurethane R&D Support:

Reviewing existing rubber and polyurethane moulds

Identifying design changes to improve accuracy or repeatability

Modifying tooling to simplify production

Reducing defects, rework, or material waste

Small design or tooling changes can significantly improve manufacturability and long-term component performance

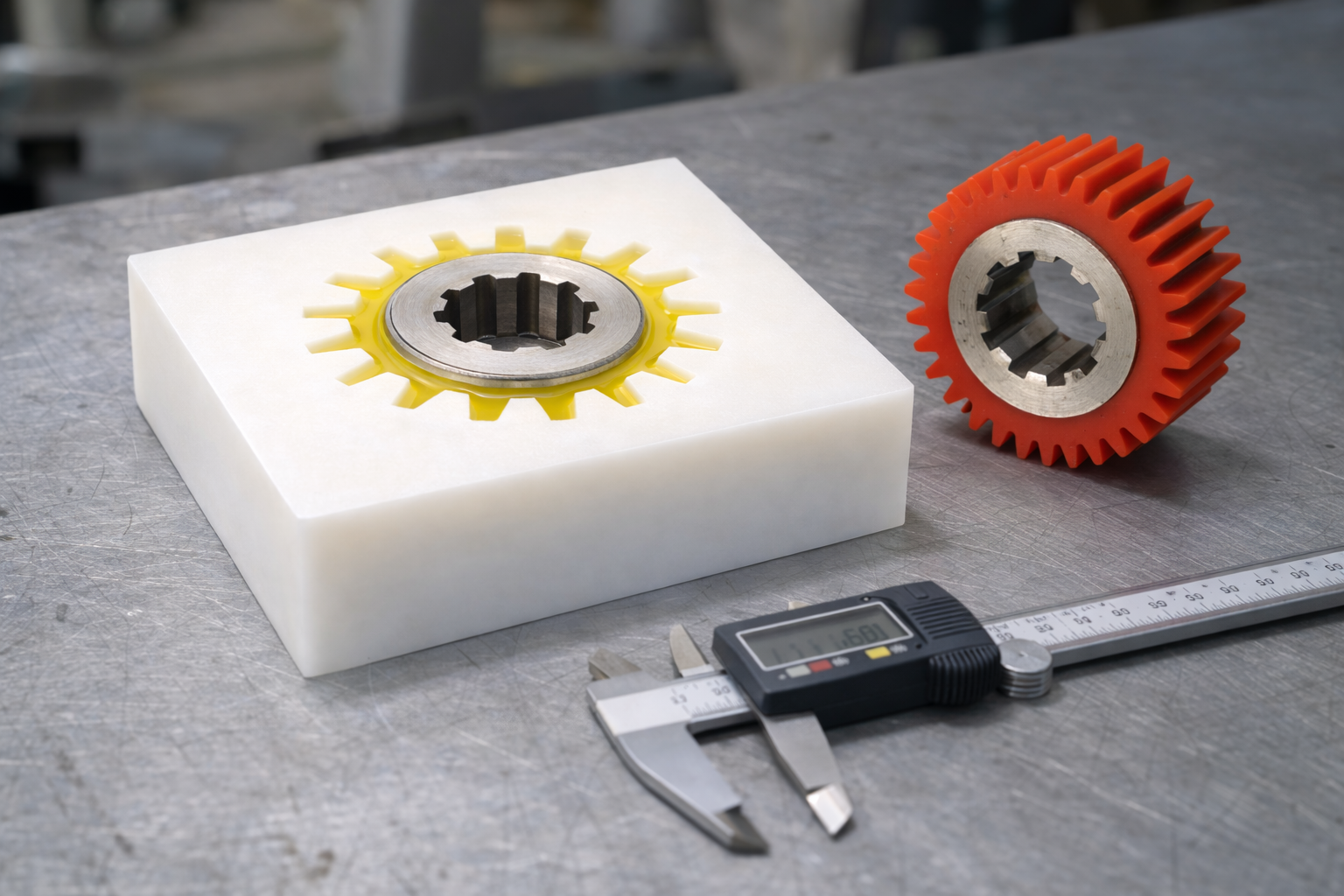

Prototyping & Product Validation

Before committing to full-scale production, Dorlen Rubber supports prototype development and validation. Prototyping allows designs to be tested and refined before production tooling or volume manufacture begins.

This stage helps confirm:

Component fit and dimensional accuracy

Material hardness and flexibility

Functional performance under operating conditions

By validating components early, clients reduce risk and avoid costly redesigns later in the manufacturing process.

Failure Analysis & Performance Improvement

When components fail prematurely or underperform in service, Dorlen Rubber provides failure analysis support to identify root causes and recommend improvements.

This may involve:

Reviewing operating conditions and application environment

Assessing material selection and design suitability

Identifying wear patterns, fatigue, or environmental degradation

Recommending design changes or alternative materials

The goal is to improve reliability, extend service life, and reduce unplanned downtime.

Process & Production Improvements

Dorlen Rubber’s rubber & polyurethane R&D capability also focuses on improving production efficiency. Our team works to identify opportunities to refine manufacturing processes and tooling to reduce lead times and minimise waste.

Process improvement support may be:

Optimising moulding or casting processes

Adjusting tooling to improve flow or curing

Reducing cycle times

Improving consistency and yield

These improvements help deliver better outcomes for both performance and cost efficiency.

Material Development & Certification Support

While compound development and formal certification are not performed in-house, Dorlen Rubber can coordinate and manage third-party material development and certification when required.

Liaising with compound developers

Assisting with material selection for specific applications

Organising third-party testing or certification

Ensuring materials meet performance or compliance requirements

By managing this process on behalf of clients, Dorlen Rubber helps streamline development and reduce complexity.

Industries We Support

Our research and development services support a wide range of industries, including:

Manufacturing and automation

Mining and resources

Infrastructure and construction

Industrial machinery and equipment

Material handling and processing

R&D support is available for both new component development and existing product improvement.

Why Use Dorlen Rubber’s In-House R&D?

Practical, manufacturing-focused development

Experience across rubber and polyurethane applications

Early-stage risk reduction through prototyping

Improved component performance and service life

Reduced production waste and lead times

Coordinated material development support

Dorlen Rubber focuses on delivering development solutions that translate into real-world performance improvements.

Trusted Australian Manufacturing Partner

Dorlen Rubber is a trusted Australian manufacturer providing in-house research and development support as part of our broader rubber and polyurethane manufacturing capabilities. Close collaboration, technical expertise, and practical problem-solving ensure our R&D services deliver measurable value.

By integrating development with manufacturing, we help clients move from concept to production with confidence.

Talk to Dorlen Rubber About Rubber & Polyurethane R&D Solutions

If you need a project built from the ground up, or are having issues with an existing product or production line give us a call.